At Pepper Home we believe that furniture is more than just something you use. That’s why we've partnered with some of the country’s most talented craftspeople, from visionary designers to trusted American manufacturers. We start with thoughtful design, carefully selecting materials that are both high quality and sustainable. Each piece is made to order, minimizing waste and maximizing attention to detail. Our process blends artistry and expertise. Each material is chosen for its durability, beauty, and impact in the environment. From the sturdy wood frames to the hand finished fabrics, we focus on creating pieces that will last a lifetime. Here’s a behind-the-scenes look at how your furniture is made, from the first click to the final stitch.

It Starts with Your Order

Once your order is placed, it’s sent directly to our manufacturing partners. Each piece is built from scratch—no inventory, no overproduction—just one-of-a-kind craftsmanship tailored to you.

Frame Construction

Every piece begins with a strong foundation. All of our frames are bench made in house to our customer’s specifications using NC kiln-dried maple or engineered hardwood. Our skilled craftspeople use a variety of joinery techniques—including mortise and tenon joints, dowels, screws, and staples—to ensure each frame is incredibly durable.

When it comes to beds and headboards, our construction is especially thoughtful. We use a double layer of engineered hardwood, layered and interlocked for maximum strength. The center is framed to allow for the same kind of strapping and padding typically found in a chair seat, giving you a softer, more comfortable surface to lean against. Each headboard features 19” high upholstered legs that are built into the structure—not attached separately—adding stability and strength. The space between the legs is intentionally left open to ensure easy access to electrical outlets behind the headboard. This design reduces the overall weight of the headboard by more than 20 pounds and significantly cuts down on lumber waste, resulting in a lower environmental impact and more efficient shipping.

The Spring Up

For chairs and benches, next up is the “spring up,” a foundational step in traditional upholstery. Here, the seat support system, made of coil or sinuous springs, is carefully installed and secured to the frame of chairs and benches. This step is essential to the comfort and longevity of your piece. The springs are positioned, tied, and stabilized to provide even weight distribution and resilient support for years to come.

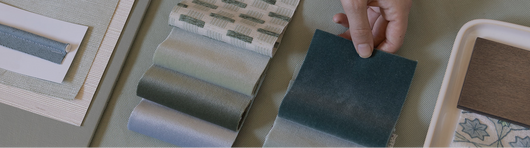

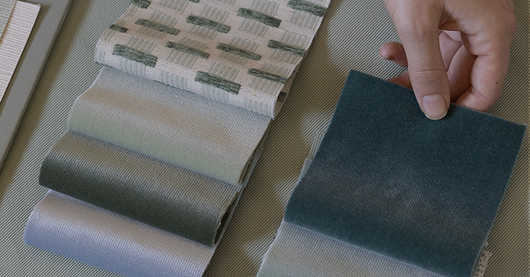

Cut & Sew

While the frame and base are being constructed, our Cut & Sew team prepares the fabric for upholstery. Every piece of fabric is laid out and cut by hand. Our team takes great care to pattern match when needed and to highlight the unique weave, texture, and beauty of your chosen material. The fabric you select influences the cutting process—a detailed floral, for example, requires more yardage than a solid velvet to ensure the pattern is beautifully displayed.

The Cushioning

Before the cushions are added to a chair or bench, we install an extra layer of padding to protect against the hardwood frame and springs. This creates a smooth, supportive base that improves comfort and helps prevent fabric wear over time.

Our standard seat cushions are made with a premium spring down-blend—the most comfortable option available. Inside each cushion is a high-grade polyurethane foam “box” filled with individually wrapped coil springs. This is then encased in a plush down-blend ticking bag, delivering multiple layers of comfort, structure, and support.

Upholstery

Now for the fun part—upholstery. This is where your piece truly comes to life. Our craftspeople secure the fabric with precision, apply any welting or trim, and attach the final details like your chosen leg style. Every fold, seam, and staple is done by hand with care and expertise.

Inspection and Packaging

Before your furniture leaves our factory, it undergoes a meticulous inspection. We check every stitch, seam, and surface to ensure it meets our high standards. Finally, your piece is packaged with care using repurposed materials from our furniture-making process—a sustainable choice that helps protect each piece in transit. From frame to finish, we’re proud of every step that goes into creating something truly special for your home.

Comments